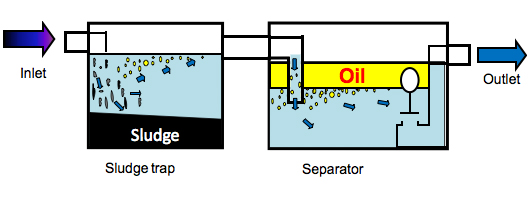

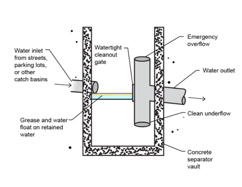

Oil water separators are gravity based pieces of equipment that separate light liquids, such as mineral oils, fuels and hydrocarbons, and suspended solids from polluted water before it is discharged into the sewer system. Light liquids (oil) have a specific density less than 1 (water). Solids (sludge) have a specific density greater than 1.

- Gas station, parking area, truck yard

- Car dealership, auto repair shop, car wash

- Bus garage, military hangar and storage facility

- Fire station

- Engine cleaning, workshops, vehicle recovery

- Transfer stations, tank pits, transformer stations

- Airport apron, railway station, container terminal

- Industrial facilities with risk of accidental oil spills

Municipal sewer bylaws and provincial and federal environmental laws describe situations where oil water separators are required. Legislation helps to minimize water pollution and maintain clean water for society and future generations.

- All oil water separators in the construction industry are based on gravity

- Oils have a specific gravity (0.8 – 0.94) less than water (1) – they float to the surface of the water

- Solids, with a specific gravity higher than water, sink to the bottom

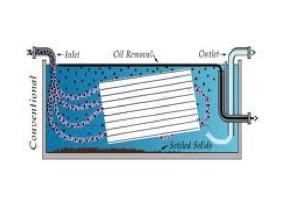

- Oil water separators were simple large boxes, usually concrete, in which the separation process took place

- The time polluted water spends in the separator from the inlet to outlet is called THE RETENTION TIME

- The larger the box, the more retention time, resulting in better separation

No. The term ‘oil’ refers to hydrocarbon derivatives. Grease, F.O.G., from the food industry and fats from animal and vegetable sources behave differently than ‘oil’, therefore, kitchen based grease requires an ACO grease separator. Visit acousa.com for more information.

Yes. As a general rule gravity based oil water separators should not be used with oils that have been emulsified as the separators are unable to separate such oils.

1. Spill Control Type Separator – limited performance used for small spills, not capable of separating dispersed oil

2. American Petroleum Type Separator – Baffled tank that can separate ‘free’ (unemulsified) oil but requires a large volume to be effective

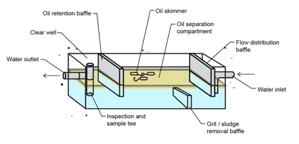

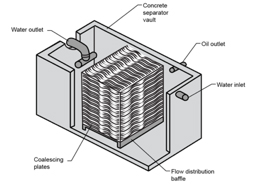

3. Coalescing Separator – separator can separate free oil in a much smaller volume because of surface area provided for oil collection by coalescing unit. (Either cylinder or plates)

Oil water separator capacity is determined by “time of retention”. This is the time an oil particle spends in the separator prior to exiting. The time needed for an oil particle to rise to the surface must be shorter than the time of retention. Separators with a longer time of retention are more efficient. Time of retention can be extended by increasing separator tank size. It is common for simple separators to be sized by tank volume.

ACO Oleopator P separators eliminate the need for larger tanks with the use of a coalescence unit. The coalescence unit allows for highly efficient separation in a small, inexpensive tank by not allowing fine oil particles through the coalescence unit – thus extending retention time indefinitely. This allows the calculation of sludge capacity in coordination with the flow rates. The user does not have to pay for unnecessary storage capacity resulting from time of retention.

ACO Oleopator P separators have modern design driven by the European standard EN858 that complies with UL 2215. They provide market leading oil separation efficiency in a compact tank. Oleopator P separators have a mechanical valve that shuts off automatically when maximum oil capacity is reached. This protects the sewer system, equipment and environment.

The units are competitively priced, inexpensive to install, and maintain, and come with a 50 year structural warranty that protects against leaks.

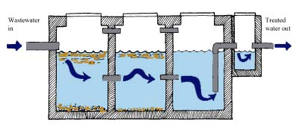

Baffle Separation

- Because of space and cost, tanks got smaller

- Different techniques used to increase retention time, hence efficiency –

- Multiple chambers inside tanks

- Baffles to slow flow speed and/or direct flow

Coalescent Separation

- Coalescing units added inside separators –

- Flat plate coalescers

- Plastic corrugated coalescing media

- Honeycomb coalescers

- Vertical tube coalescers

- Knitted mesh coalescers

- With smaller boxes, and adding coalescing units inside separators, the cost of the product is reduced – but maintenance costs rise

- Coalescing separators are the most efficient in today’s market

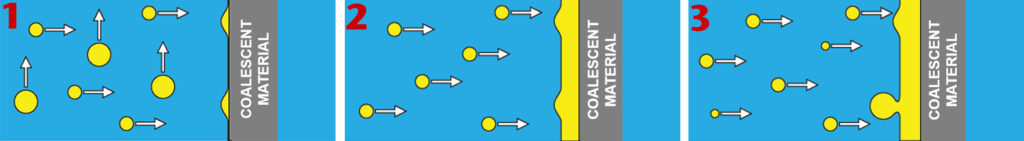

- Coalescence –

The process by which two or more droplets, bubbles or particles, merge during contact to form a single droplet, bubble or particle.

- In oil water separators, the coalescence units force fine oil particles to combine into large ones, which float to the surface

- Polluted water includes solid particles – these can clog coalescence units. Proper scheduled maintenance prevents this.

- Easy to clean coalescence units provide a significant end user advantage