ACO, Inc. Featured on Inside The Blueprint

ACO, INC. StormBrixx® Stormwater Detention and Infiltration System is a Revolutionary Innovation in Sub-Surface Water Treatment Systems

The ongoing impact from climate change will require changes to our stormwater infrastructure and require fresh innovative approaches to manage the catastrophic results of localized flooding. A report card from the American Society of Civil Engineers in April 2021 pointed out that annual flooding between 2004 – 2014 cost urban communities approximately $9 billion in damages. They recommend that there should be a localized understanding of the risk associated with flooding that informs decisions on current and future regulatory expectations and land-use practices.

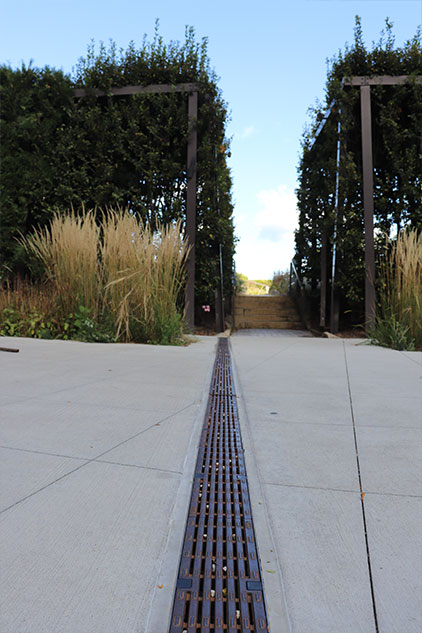

ACO, Inc. designs and develops products that help manage and mitigate the risks associated with urban flooding and stormwater management. In this episode of Inside The Blueprint, we get a behind the scenes look at their patented plastic geocellular stormwater management system — StormBrixx®.

It is designed specifically to offer a new, innovative solution for civil engineers, water resource engineers, and stormwater management supervisors worldwide. The system’s versatility enables runoff from the hydrological cycle to be collected, cleaned, stored, and released back into the natural environment at a controlled rate.