In a world where environmental pollution controls are becoming stricter ACO has developed products to help businesses comply with these regulations. Products are designed with easy installation, operation and maintenance in mind to ensure full customer satisfaction. ACO Environment produces oil, water, and solids separators and spill containment systems manufactured from corrosion resistant fiberglass, polyethylene, and other materials.

ACO oil water separators are designed and built to protect our water by removing even the finest particles of mineral oils, fuels and hydrocarbons from wastewater and storm water in the most efficient way. Oil water separators are typically used in facilities such as vehicle service storage, parking areas, fuel stations and any location where oil spills are possible.

Steel edge modular trench system in 100 mm (4″), 200 mm (8″) & 300 mm (12″) internal width

Heavy duty iron edged, modular trench system in 100 mm (4″), 200 mm (8″) & 300 mm (12″) internal width

Shallow depth trench drain system in 100 mm (4″), 200 mm (8″) & 300 mm (12″) internal width

Technical Information

- What is the expected water flow through separator?

- Solids and sludge storage capacity needed?

- Oil storage capacity needed?

- What vehicles (loads) will go over the separator?

- What is the inlet/outlet pipe depth?

- Are alarms required?

How to calculate flow

NS = ( Qr + fx x Qs ) x fd

NS = Separator nominal size – Gallons per minute (GPM) or L Liters per second (L/sec)

Qr = Designed stormwater flow -rainfall (GPM or L/sec)

Qs = Designed wastewater flow – other liquids (GPM or L/sec)

fd = 0.9; Nominal density factor for light liquid (oil)

fx = 2; Generally used for all types of waste water from industrial processes, vehicle washing, cleaning of oil covered parts or other sources, eg. gas station

fx = 1; Only for containment of accidental oil spills

Capacity for sludge storage must be provided for all separators – either as an integral part of the separator or as a separate upstream unit.

The minimum size of the sludge storage capacity is calculated as follows:

Imperial

C = NS x 1.6

C = sludge storage capacity (gallons)

NS = separator nominal size (GPM)

Metric

C = NS x 100

C = sludge storage capacity (Liters)

NS = separator nominal size (L/sec)

Oil storage capacity is defined as ‘the volume of separated oil that can be stored without any oil entering the inlet or outlet of the separator’.

The minimum oil storage volume (V) is calculated as follows:

Imperial

V = NS x 0.16

V = oil storage capacity (gallons)

NS = separator nominal size (GPM)

Metric

V = NS x 10

V= oil storage capacity (liters)

NS = separator nominal size (l/sec)

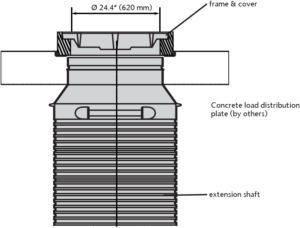

Pedestrian Rated Cover

Separator is located where there is no vehicular access. Maximum allowable load, including dynamic factor, is – 3,000 lbs or 44 psi

Vehicle Rated Cover

Separator is located where heavy vehicular traffic is possible*.

Load distribution plate under cover is required! Maximum allowable load, including dynamic factor, is – 89,000 lbs or 1,182 psi

*Never place separator in high volume traffic areas

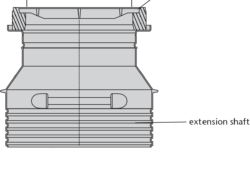

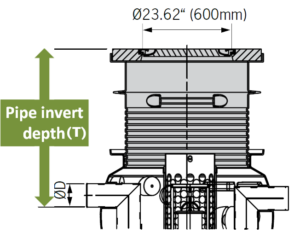

When selecting a product pipe invert depth (T) is critical.

Most separators will work within a certain range of depths.

If designed pipe invert depths are outside of the ranges, expensive additional work may be required or product may be unsuitable for use

With any oil water separator. maintenance is critical to ensure the designed operation of the product for the maximum period of time.

- Facility operator must be familiar with how the separator works

- Maintenance schedule must be in place

- Alarm systems can be used to alert for failure due to excessive oil or sludge

- Clean the coalescence unit

- Timing depends on usage, minimum every 6 months

- Periodically empty separator and clean inside

- Timing depends on usage, minimum every 12 months*

- Keep maintenance log for records

*Most municipalities have by-laws regulating frequency of oil/water separator maintenance. These must be known and followed by the facility operator.