FlowDrain — FG200″

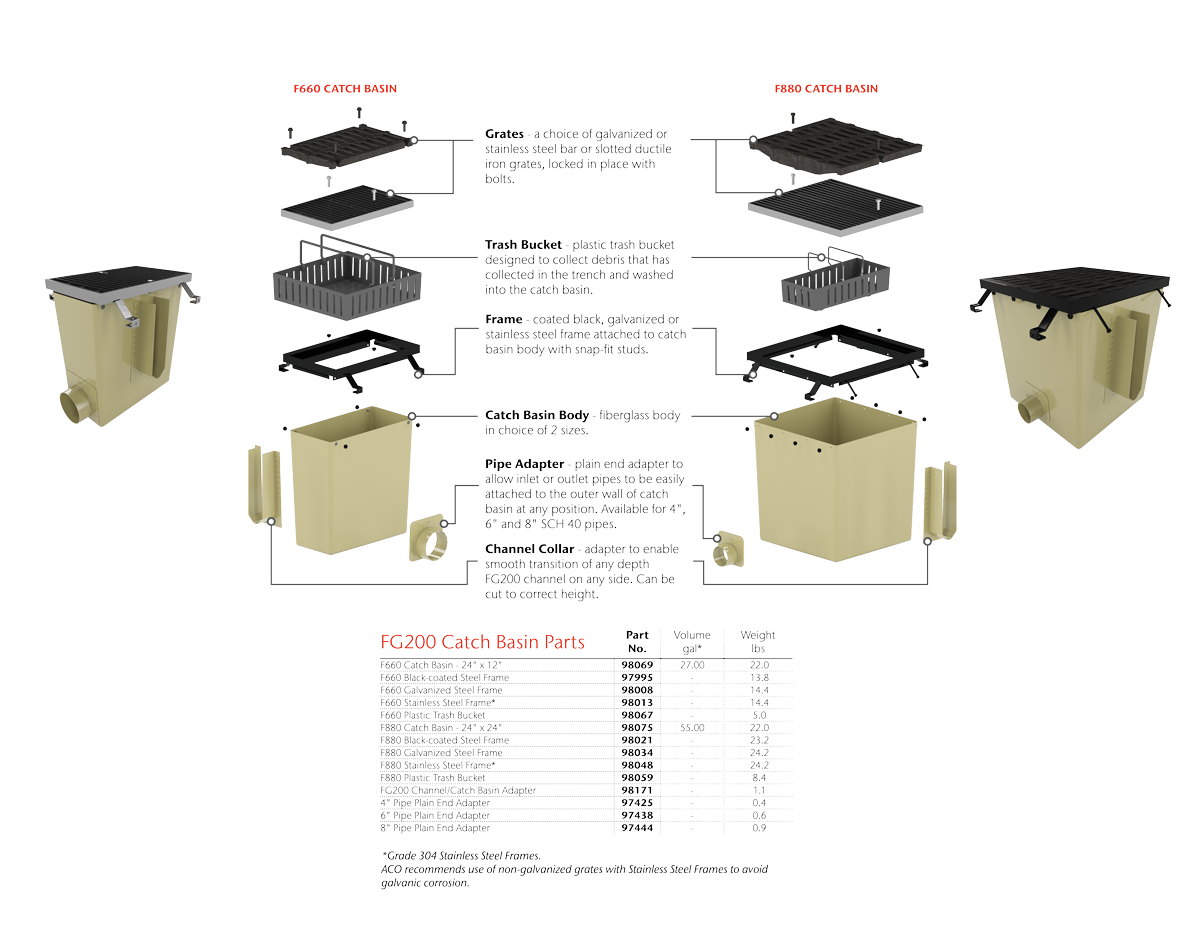

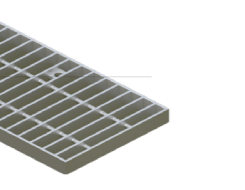

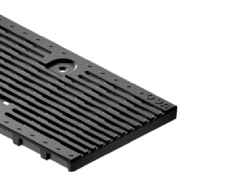

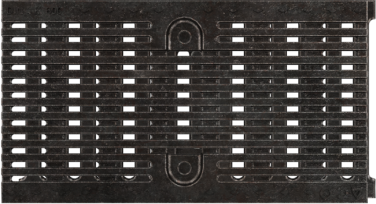

When selecting the grate there are a couple of factors that have to be considered, including the load classification (resistance to failure), slot pattern (water intake), material (corrosion resistance, etc.), locking (making grate captive to channel), and aesthetics (finished look). Click here for further information on grate selection.

Try the ACO Visualizer to see options of grates with different surfaces! View ACO Visualizer

Key

ADA compliant

Compliant with Americans with Disabilities Act of 2010, Section 302.3

Heel-resistant

ASME A112.6.3 - 2001 Heel-resistant slot width less than 0.31" (8 mm)

Heel-safe

Heel-safe slot width equal or less than 0.25" (6.5 mm)

Anti-slip grates

BPN over 24 (test results available)

Bicycle safe

Compliant to Australian Standard AS 3996 - 2006

Non-metallic

No metallic/magnetic parts included

| Part No. | Length in (m) |

Slot size in |

Intake area in2 | Weight lbs | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LOAD CLASS C (EN 1433) - 56,202 LBS - 1,934 PSI COMMERCIAL VEHICLE TRAFFIC | ||||||||||||

| BAR STEEL |

|

4-BOLT GRATES | ||||||||||

|

Galvanized | 93899 | 36.00 (0.9) | 1.0 x 3.6 | 264.0 | 28.6 |

✓ |

× |

× |

× |

× |

|

| Stainless | 142224 | 36.00 (0.9) | 264.0 | 28.6 | ||||||||

Key

ADA compliant

Compliant with Americans with Disabilities Act of 2010, Section 302.3

Heel-resistant

ASME A112.6.3 - 2001 Heel-resistant slot width less than 0.31" (8 mm)

Heel-safe

Heel-safe slot width equal or less than 0.25" (6.5 mm)

Anti-slip grates

BPN over 24 (test results available)

Bicycle safe

Compliant to Australian Standard AS 3996 - 2006

Non-metallic

No metallic/magnetic parts included

| Part No. | Length in (m) |

Slot size in |

Intake area in2 |

Weight lbs | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LOAD CLASS E (EN 1433) - 134,885 LBS - 4,641 PSI INDUSTRIAL TRAFFIC | ||||||||||||

| SLOTTED IRON |

|

4-BOLT GRATES | ||||||||||

|

Iron | 93896 | 18.00 (0.45) | 0.61 x 7.87 | 58.7 | 25.2 |

✓ |

× |

× |

× |

× |

|

| LONGITUDINAL IRON |

|

4-BOLT GRATES | ||||||||||

|

Iron | 93893 | 18.00 (0.45) | 1.75 x 0.25 | 35.0 | 28.2 |

✓ |

✓ |

✓ |

✓ |

✓ |

|

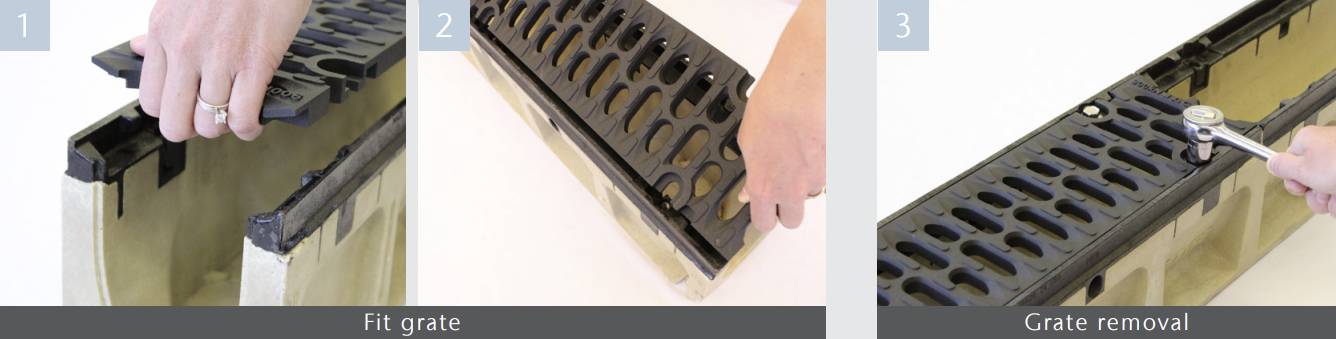

4-BOLT GRATES

Position grate onto channel, align holes in grate with matching holes in edge rail.

Use wrench or socket set to tighten. If using a torque wrench, do not set to more than 15 ft. lbs.

To remove grates, use wrench or socket set. Carefully store bolts for refitting of grates. Tamper-resistant bolts require a tamperresistant drive bit

|

Part No.

|

Invert Depth

|

Overall Depth

|

Volume

|

Weight

|

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

in

|

mm

|

in

|

mm

|

gal

|

lbs

|

||||||

| female | male | female | male | female | male | female | male | ||||

| F801 Sloped Channel – 108″ (2.75 m) | 99006 | 6.75 | 7.88 | 172 | 200 | 6.88 | 8.01 | 175 | 203 | 18.37 | 11.0 |

| F802 Sloped Channel – 108″ (2.75 m) | 99013 | 7.88 | 9.00 | 200 | 229 | 8.01 | 9.13 | 203 | 232 | 22.58 | 12.0 |

| F803 Sloped Channel – 108″ (2.75 m) | 99021 | 9.00 | 10.13 | 229 | 257 | 9.13 | 10.26 | 232 | 260 | 26.79 | 13.0 |

| F803N Constant Depth Channel – 108″ (2.75 m) | 99048 | 10.13 | 10.13 | 257 | 257 | 10.26 | 10.26 | 260 | 260 | 28.80 | 15.5 |

| F803N3 Constant Depth Channel – 36″ (0.915 m) | 99034 | 10.13 | 10.13 | 257 | 257 | 10.26 | 10.26 | 260 | 260 | 9.60 | 5.2 |

| F804 Sloped Channel – 108″ (2.75 m) | 99055 | 10.13 | 11.25 | 257 | 286 | 10.26 | 11.38 | 260 | 289 | 31.00 | 14.1 |

| F805 Sloped Channel – 108″ (2.75 m) | 99062 | 11.25 | 12.38 | 286 | 314 | 11.38 | 12.51 | 289 | 318 | 35.21 | 15.2 |

| F806 Sloped Channel – 108″ (2.75 m) | 99071 | 12.38 | 13.50 | 314 | 343 | 12.51 | 13.63 | 318 | 346 | 39.42 | 16.3 |

| F806N Constant Depth Channel – 108″ (2.75 m) | 99095 | 13.50 | 13.50 | 343 | 343 | 13.63 | 13.63 | 346 | 346 | 41.50 | 16.3 |

| F806N3 Constant Depth Channel – 36″ (0.915 m) | 99084 | 13.50 | 13.50 | 343 | 343 | 13.63 | 13.63 | 346 | 346 | 13.83 | 5.5 |

| F807 Sloped Channel – 108″ (2.75 m) | 99109 | 13.50 | 14.63 | 343 | 371 | 12.63 | 14.76 | 346 | 375 | 43.63 | 17.4 |

| F808 Sloped Channel – 108″ (2.75 m) | 99116 | 14.63 | 15.75 | 371 | 400 | 14.76 | 15.88 | 375 | 403 | 47.84 | 18.5 |

| F809 Sloped Channel – 108″ (2.75 m) | 99123 | 15.75 | 16.87 | 400 | 429 | 15.88 | 17.00 | 403 | 432 | 52.05 | 19.6 |

| F809N Constant Depth Channel – 108″ (2.75 m) | 99145 | 16.87 | 16.87 | 429 | 429 | 17.00 | 17.00 | 432 | 432 | 54.10 | 19.6 |

| F809N3 Constant Depth Channel – 36″ (0.915 m) | 99132 | 16.87 | 16.87 | 429 | 429 | 17.00 | 17.00 | 432 | 432 | 18.00 | 6.5 |

| F810 Sloped Channel – 108″ (2.75 m) | 99156 | 16.87 | 18.00 | 429 | 457 | 17.00 | 18.13 | 432 | 460 | 56.26 | 20.7 |

| F811 Sloped Channel – 108″ (2.75 m) | 99162 | 18.00 | 19.13 | 457 | 486 | 18.13 | 19.26 | 460 | 489 | 60.47 | 21.8 |

| F812 Sloped Channel – 108″ (2.75 m) | 99175 | 19.13 | 20.25 | 486 | 514 | 19.26 | 20.38 | 489 | 518 | 64.68 | 23.0 |

| F812N Constant Depth Channel – 108″ (2.75 m) | 99192 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | 66.76 | 23.0 |

| F812N3 Constant Depth Channel – 36″ (0.915 m) | 99186 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | 2.25 | 7.7 |

| Black-coated Steel Frame – 108″ (2.75 m) | 97066 | – | – | – | – | – | – | – | – | – | 57.9 |

| Black-coated Steel Frame – 36″ (0.915 m) | 98524 | – | – | – | – | – | – | – | – | – | 19.3 |

| Galvanized Steel Frame – 108″ (2.75 m) | 97079 | – | – | – | – | – | – | – | – | – | 57.9 |

| Galvanized Steel Frame – 36″ (0.915 m) | 98538 | – | – | – | – | – | – | – | – | – | 19.3 |

| Stainless Steel Frame – 108″ (2.75 m)* | 97087 | – | – | – | – | – | – | – | – | – | 57.9 |

| Stainless Steel Frame – 36″ (0.915 m)* | 98545 | – | – | – | – | – | – | – | – | – | 19.3 |

| Closing Cap (female) with Black End Frame | 98365 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | – | 1.1 |

| Closing Cap (female) with Galvanized Steel End Frame | 98386 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | – | 1.1 |

| Closing Cap (female) with Stainless Steel End Frame | 98375 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | – | 1.1 |

| Closing Cap (male) with Black End Frame | 98363 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | – | 1.3 |

| Closing Cap (male) with Galvanized Steel End Frame | 98382 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | – | 1.3 |

| Closing Cap (male) with Stainless Steel End Frame | 98372 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | – | 1.3 |

| Outlet Cap (male) with Black End Frame | 98361 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | – | 1.8 |

| Outlet Cap (male) with Galvanized Steel End Frame | 98381 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | – | 1.8 |

| Outlet Cap (male) with Stainless Steel End Frame | 98373 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | – | 1.8 |

| Vertical Outlet Adapter – 4″, 6″ or 8″ Outlet | 98103 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | – | 1.6 |

| Notes 1. Invert depths are for the channel body & frame assembled. 2. Channel weights are for fiberglass body only. 3. Closing/Outlet caps can be cut down to suit all channels. 4. Add 2″ to length of each channel for female joining flange (only applicable at shallowest end of trench run). 5. Frames supplied with plastic snap-fit studs for connecting to fiberglass body. * Grade 304 stainless steel frames, ACO recommends the use of non-galvanized grates with stainless steel frames to avoid galvanic corrosion. |

|||||||||||

|

FG200 Accessories

|

Part No. |

Invert Depth

|

Overall Depth

|

Weight

|

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

in

|

mm

|

in

|

mm

|

lbs

|

|||||||

| female | male | female | male | female | male | female | male | ||||

|

Closing Cap (female) with Black End Frame | 98365 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | 1.1 |

|

Closing Cap (female) with Galvanized Steel End Frame | 98386 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | 1.1 |

|

Closing Cap (female) with Stainless Steel End Frame | 98375 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | 1.1 |

|

Closing Cap (male) with Black End Frame | 98363 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | 1.3 |

|

Closing Cap (male) with Galvanized Steel End Frame | 98382 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | 1.3 |

|

Closing Cap (male) with Stainless Steel End Frame | 98372 | – | – | – | – | 20.38 | 20.38 | 518 | 518 | 1.3 |

|

Outlet Cap (male) with Black End Frame | 98361 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | 1.8 |

|

Outlet Cap (male) with Galvanized Steel End Frame |

98381 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | 1.8 |

|

Outlet Cap (male) with Stainless Steel End Frame | 98373 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | 1.8 |

|

Vertical Outlet Adapter – 4″, 6″ or 8″ Outlet |

98103 | 20.25 | 20.25 | 514 | 514 | 20.38 | 20.38 | 518 | 518 | 1.6 |

DR100 ACO Drain Catalog Part 1 – Introduction

DR100 ACO Drain Catalog Part 4 – SlabDrain

DR100 ACO Drain Catalog Part 5 – Technical Support

DL056 FlowDrain Brochure ENGLISH

DL056 FlowDrain Brochure SPANISH

3-Part Spec

FlowDrain - High Capacity Trench Drain 3-Part Spec Sheet

FG200

FlowDrain - FG200 Galvanized Steel Bar Grate Spec Sheet

FlowDrain - FG200 Stainless Steel Bar Grate Spec Sheet

FlowDrain - FG200 Ductile Iron Longitudinal Grate Spec Sheet

FlowDrain - FG200 Channel System With Black Coated Frame Spec Sheet

FlowDrain - FG200 Channel System With Galvanized Steel Frame Spec Sheet

FlowDrain - FG200 Channel System With Stainless Steel Frame Spec Sheet

FlowDrain - FG200 Ductile Iron Slotted Grate Spec Sheet

F660

FlowDrain - F660 Galvanized Steel Bar Grate Spec Sheet

FlowDrain - F660 Catch Basin With Black Coated Frame Spec Sheet

FlowDrain - F660 Catch Basin With Galvanized Steel Frame Spec Sheet

FlowDrain - F660 Catch Basin With Stainless Steel Frame Spec Sheet

FlowDrain - F660 Ductile Iron Slotted Grate Spec Sheet

FlowDrain - F660 Stainless Steel Bar Grate Spec Sheet

F880

FlowDrain - F880 Catch Basin With Black Coated Frame Spec Sheet

FlowDrain - F880 Catch Basin With Galvanized Steel Frame Spec Sheet

FlowDrain - F880 Catch Basin With Stainless Steel Frame Spec Sheet

FlowDrain - F880 Galvanized Steel Bar Grate Spec Sheet

FlowDrain - F880 Ductile Iron Slotted Grate Spec Sheet

FlowDrain - F880 Stainless Steel Bar Grate Spec Sheet

| Description | Documents | ||

|---|---|---|---|

| DWG | |||

| Black Frame | FG200, Black Frame, Class A - Exposed Asphalt Pavement | Download | |

| FG200, Black Frame, Class A - Exposed Concrete Pavement | Download | ||

| FG200, Black Frame, Class A - Exposed Paver Pavement | Download | ||

| FG200, Black Frame, Class B - Exposed Asphalt Pavement | Download | ||

| FG200, Black Frame, Class B - Exposed Concrete Pavement | Download | ||

| FG200, Black Frame, Class B - Exposed Paver Pavement | Download | ||

| FG200, Black Frame, Class C - Exposed Asphalt Pavement | Download | ||

| FG200, Black Frame, Class C - Exposed Concrete Pavement | Download | ||

| FG200, Black Frame, Class C - Exposed Paver Pavement | Download | ||

| FG200, Black Frame, Class D - Exposed Asphalt Pavement | Download | ||

| FG200, Black Frame, Class D - Exposed Concrete Pavement | Download | ||

| FG200, Black Frame, Class D - Exposed Paver Pavement | Download | ||

| FG200, Black Frame, Class E - Exposed Asphalt Pavement | Download | ||

| FG200, Black Frame, Class E - Exposed Concrete Pavement | Download | ||

| FG200, Black Frame, Class E - Exposed Paver Pavement | Download | ||

| Galvanized Frame | FG200, Galvanized Frame, Class A - Exposed Asphalt Pavement | Download | Download |

| FG200, Galvanized Frame, Class A - Exposed Concrete Pavement | Download | Download | |

| FG200, Galvanized Frame, Class A - Exposed Paver Pavement | Download | Download | |

| FG200, Galvanized Frame, Class B - Exposed Asphalt Pavement | Download | Download | |

| FG200, Galvanized Frame, Class B - Exposed Concrete Pavement | Download | Download | |

| FG200, Galvanized Frame, Class B - Exposed Paver Pavement | Download | Download | |

| FG200, Galvanized Frame, Class C - Exposed Asphalt Pavement | Download | Download | |

| FG200, Galvanized Frame, Class C - Exposed Concrete Pavement | Download | Download | |

| FG200, Galvanized Frame, Class C - Exposed Paver Pavement | Download | Download | |

| FG200, Galvanized Frame, Class D - Exposed Asphalt Pavement | Download | Download | |

| FG200, Galvanized Frame, Class D - Exposed Concrete Pavement | Download | Download | |

| FG200, Galvanized Frame, Class D - Exposed Paver Pavement | Download | Download | |

| FG200, Galvanized Frame, Class E - Exposed Asphalt Pavement | Download | Download | |

| FG200, Galvanized Frame, Class E - Exposed Concrete Pavement | Download | Download | |

| FG200, Galvanized Frame, Class E - Exposed Paver Pavement | Download | Download | |

| Stainless Steel Frame | FG200, Stainless Steel Frame, Class A - Exposed Asphalt Pavement | Download | Download |

| FG200, Stainless Steel Frame, Class A - Exposed Concrete Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class A - Exposed Paver Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class B - Exposed Asphalt Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class B - Exposed Concrete Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class B - Exposed Paver Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class C - Exposed Asphalt Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class C - Exposed Concrete Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class C - Exposed Paver Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class D - Exposed Asphalt Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class D - Exposed Concrete Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class D - Exposed Paver Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class E - Exposed Asphalt Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class E - Exposed Concrete Pavement | Download | Download | |

| FG200, Stainless Steel Frame, Class E - Exposed Paver Pavement | Download | Download | |

| Catch Basins | Catch Basin, 880, Class A-E - Asphalt | Download | |

| Catch Basin, 880, Class A-E - Asphalt | Download | ||

| Catch Basin, 880, Class A-E - Concrete | Download | ||

| Catch Basin, 660, Class A-E - Asphalt | Download | ||

| Catch Basin, 660, Class A-E - Asphalt | Download | ||

| Catch Basin, 660, Class A-E - Asphalt | Download | ||

| Catch Basin, 660, Class A-C - Concrete | Download | ||

| Project Name | City | State | Product Line | Product Family | Product | Product 2 Line | Product 2 Family | Product 2 | Location | pdf Links |

|---|---|---|---|---|---|---|---|---|---|---|

| Colorado Springs Airport Terminal | Denver | CO | ACO Drain | FlowDrain | FG200 | Airport | Download | |||

| Coshocton County Airport | Coschocton | OH | ACO Drain | FlowDrain | FG200 | Airport | Download | |||

| Crestridge and Knotts Roads Project | Lexington | SC | ACO Drain | FlowDrain | FG200 | Roadways | Download | |||

| Fairfax County Fire & Rescue, Herndon Station | Herndon | VA | ACO Drain | FlowDrain | FG200 | Public Services | Download | |||

| Great Lakes National Cemetary | Holly | MI | ACO Drain | FlowDrain | FG200 | Monument/Park | Download | |||

| Holloman Air Force Base | Holloman AFB | NM | ACO Drain | FlowDrain | FG200 | Public Services | Download | |||

| Indianapolis Speedway Pedestrian Walkway | Indianapolis | IN | ACO Drain | FlowDrain | FG200 | Recreational | Download | |||

| Jesse Owens Track and Soccer Complex Ohio State University | Columbus | OH | ACO Drain | FlowDrain | FG200 | Athletic Venues | Download | |||

| Lemon Avenue Streetscape | Sarasota | FL | ACO Drain | FlowDrain | FG200 | Roadways | Download | |||

| McCarran Airport Baggage Area | Las Vegas | NV | ACO Drain | FlowDrain | FG200 | Airport | Download | |||

| McGhee Tyson Airport Economy Parking | Knoxville | TN | ACO Drain | FlowDrain | FG200 | Airport | Download | |||

| Port of Pasco Terminal Apron | Pasco | WA | ACO Drain | FlowDrain | FG200 | Ports/Docks | Download | |||

| Reno Airport | Reno | NV | ACO Drain | FlowDrain | FG200 | Airport | Download | |||

| Salt Lake City Airport | Salt Lake City | UT | ACO Drain | FlowDrain | FG200 | Airport | Download | |||

| San Luis Obispo Airport Terminal | San Luis Obispo | CA | ACO Drain | FlowDrain | FG200 | Airport | Download | |||

| Stone Arch Bridge | Minneapolis | MN | ACO Drain | FlowDrain | FG200 | Monument/Park | Download | |||

| Sysco Inc. Loading Dock | Knoxville | TN | ACO Drain | FlowDrain | FG200 | Ports/Docks | Download | |||

| Thimble Shoals | Newport News | VA | ACO Drain | FlowDrain | FG200 | Roadways | Download | |||

| Tower of the Americas | San Antonio | TX | ACO Drain | FlowDrain | FG200 | Shopping Center | Download | |||

| University of Colorado Hospital Helipad | Aurora | CO | ACO Drain | FlowDrain | FG200 | Public Services | Download | |||

| Youngstown Warren Equipment Building | Vienna | OH | ACO Drain | FlowDrain | FG200 | Public Services | Download | |||

| St. Albans School | Washington | DC | ACO Drain | FlowDrain | FG200 | Education | Download |